|

Low Temperature and Radiation Resistant Cable

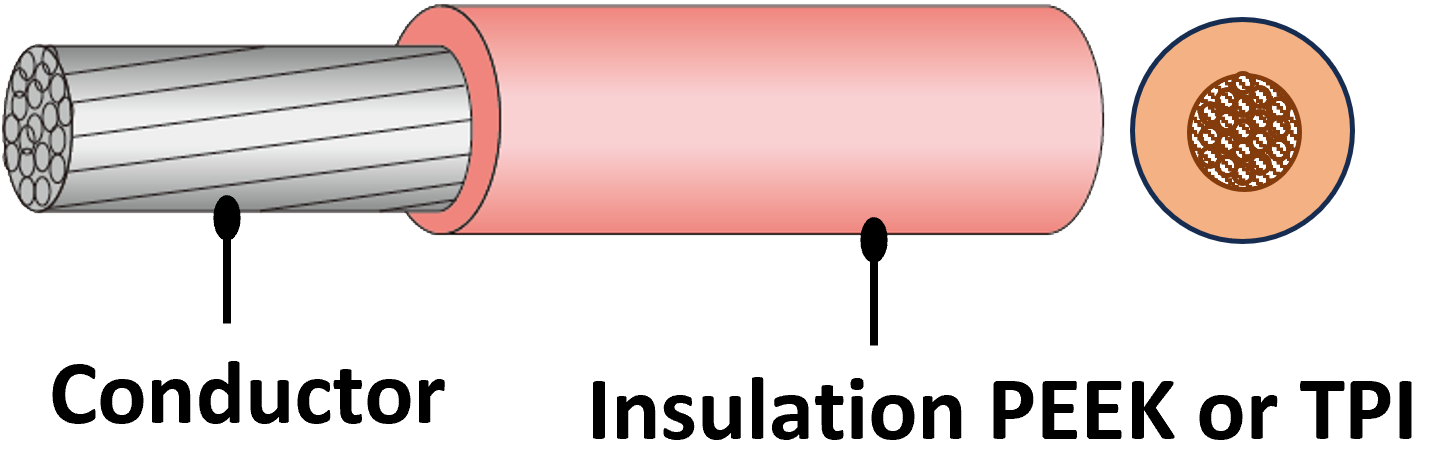

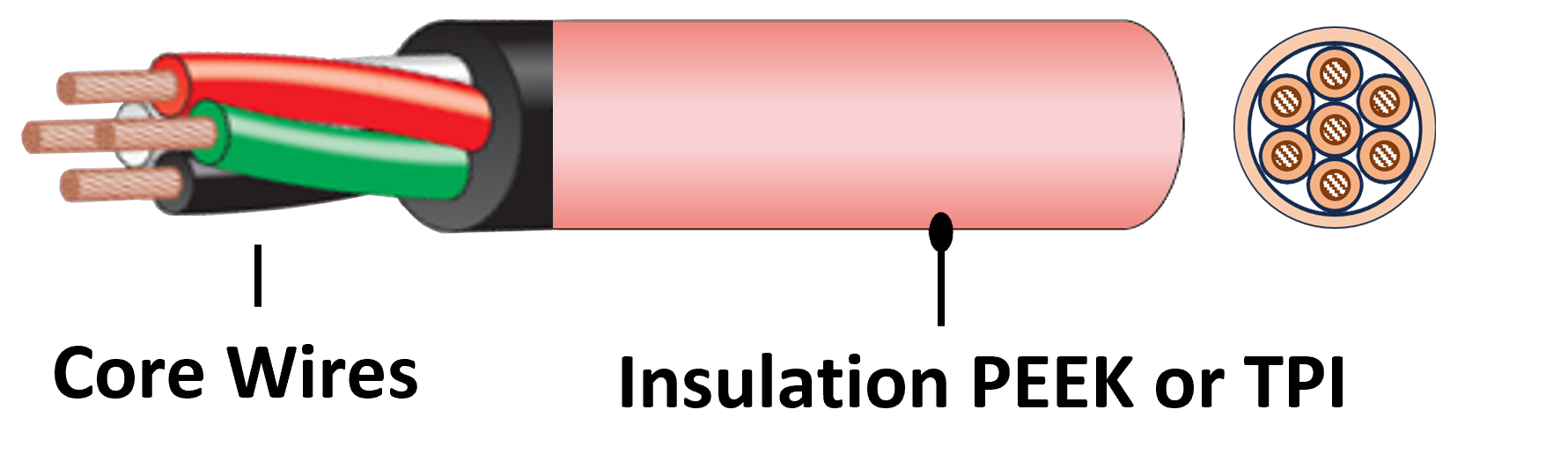

Structure

Specification

1. Temperature resistance level

PEEK Temperature range: -60°C~+250°C

PI temperature range: -200°C~+250~300°C

2. Products and specifications meet standards

- Rated voltage: 600V

-

Mechanical strength: >80Mpa

-

Scratch resistance: >10000 Cycles

3. Product standards

- Halogen free: IEC 60754-2 / EN 60754-2

Application

- Used in atomic energy industry, nuclear power/high energy physics, medical radiation resistance, internal wiring and connecting wires of aerospace instruments and meters, motor windings and other fields under extremely low temperature conditions.

-

Transportation maglev field.

-

Medical equipment MRI signal cables, detection of superconducting magnets and their feeder systems, superconducting solenoid signal cables, ultra-low temperature and high field insulated cables.

Advantages

- Low temperature resistance - It will not brittle or creep in liquid nitrogen, liquid oxygen and liquefied natural gas, and can be used at near absolute zero (-273°C) under certain conditions.

-

High limiting oxygen index, low smoke, halogen-free, flame retardant and meets EN45545-2 fire protection HL3 level.

-

High heat resistance glass transition temperature: 240℃.

-

Electrical properties such as insulation resistance and dielectric breakdown voltage are excellent and are hardly affected by temperature or humidity.

-

Corrosion resistance - Resistant to almost all chemicals and oxidants. Can be immersed in acid, alkali or oxidant for a long time without any change.

-

It has the lowest water vapor permeability and is impermeable to all gases, making it a good barrier polymer.

-

Gamma radiation resistance: 850KGy can be used for a long time.

Technical parameters:

| Technical parameters |

Size

AWG |

Copper Diameter

of litz wire

|

Insulation

Thickness |

Average outer outer

diameter D |

| |

min |

aver. |

max |

| --- |

mm2 |

mm |

mm |

| 10 |

2.588

|

>0.40~0.50 |

4.00 |

4.20 |

|

| ~ |

| 32 |

0.2032 |

>0.18~0.25 |

0.60 |

0.65 |

|

| Technical parameters |

Size

AWG |

Copper Diameter

of litz wire

|

Insulation

Thickness |

Average outer outer

diameter D |

| |

min |

aver. |

max |

| --- |

mm2 |

mm |

mm |

| 10 |

2.588

|

>0.40~0.50 |

4.00 |

4.20 |

|

| ~ |

| 32 |

0.2032 |

>0.18~0.25 |

0.60 |

0.65 |

|

| Technical parameters |

Size

AWG |

Core

Dimeter |

Cross-

section |

Stranded

Concentric) |

Number of core

wires and nominal

cross-section |

Insulation |

Sheath |

| Thickness |

Outer

diameter D |

Thickness |

Outer diameter D |

| min |

aver. |

max |

| --- |

mm |

mm2 |

--- |

mm2 |

mm |

mm |

mm |

| 14 |

2.05 |

2.50 |

19/0.41 |

2✖2.50 |

>0.35 |

2.75 |

>0.35 |

|

6.20 |

|

| |

|

19/0.41 |

3✖2.50 |

>0.35 |

2.75 |

>0.35 |

|

6.30 |

|

| |

|

19/0.41 |

4✖2.50 |

>0.35 |

2.75 |

>0.35 |

|

7.40 |

|

| ~ |

| 29 |

0.28 |

0.06 |

7/0.12 |

2✖0.06 |

|

|

>0.25 |

2.40 |

|

2.50 |

|

|

7/0.12 |

3✖0.06 |

|

|

>0.25 |

2.50 |

|

2.60 |

|

|

7/0.12 |

4✖0.06 |

|

|

>0.25 |

2.70 |

|

2.80 |

|

|

7/0.12 |

5✖0.06 |

|

|

>0.25 |

2.90 |

|

3.00 |

| |

*The number of cores, composition and insulation thickness can be specified by the customer.

*The insulation thickness of the general PEEK insulated wire without adhesive layer ranges from 0.025~2.032mm, and the AWG size is #3~#40.

|