|

Electric Wire And Cable For Nuclear Power Plants

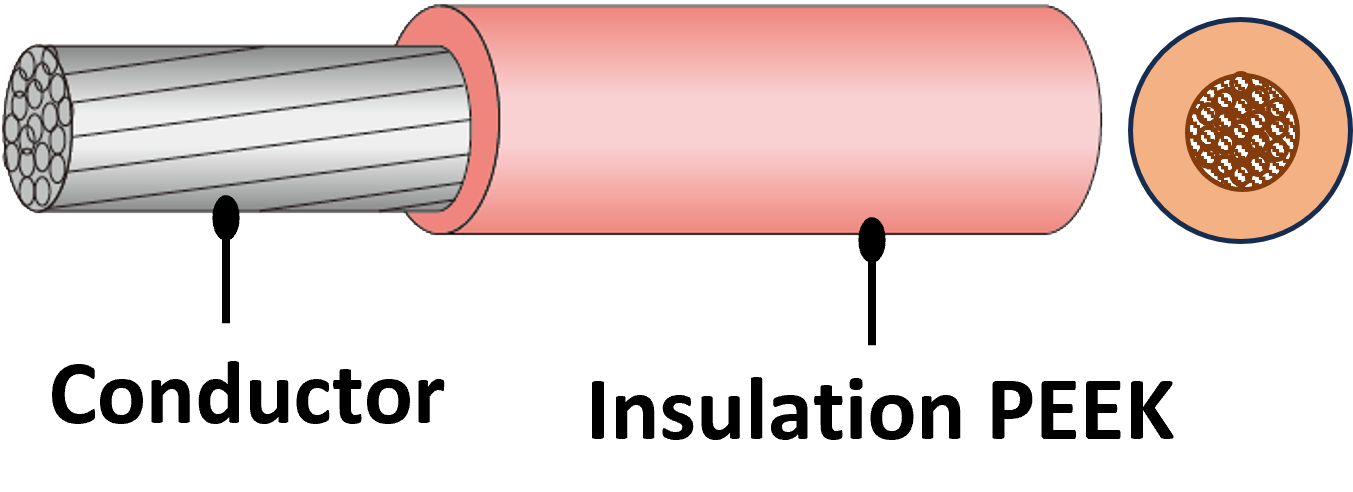

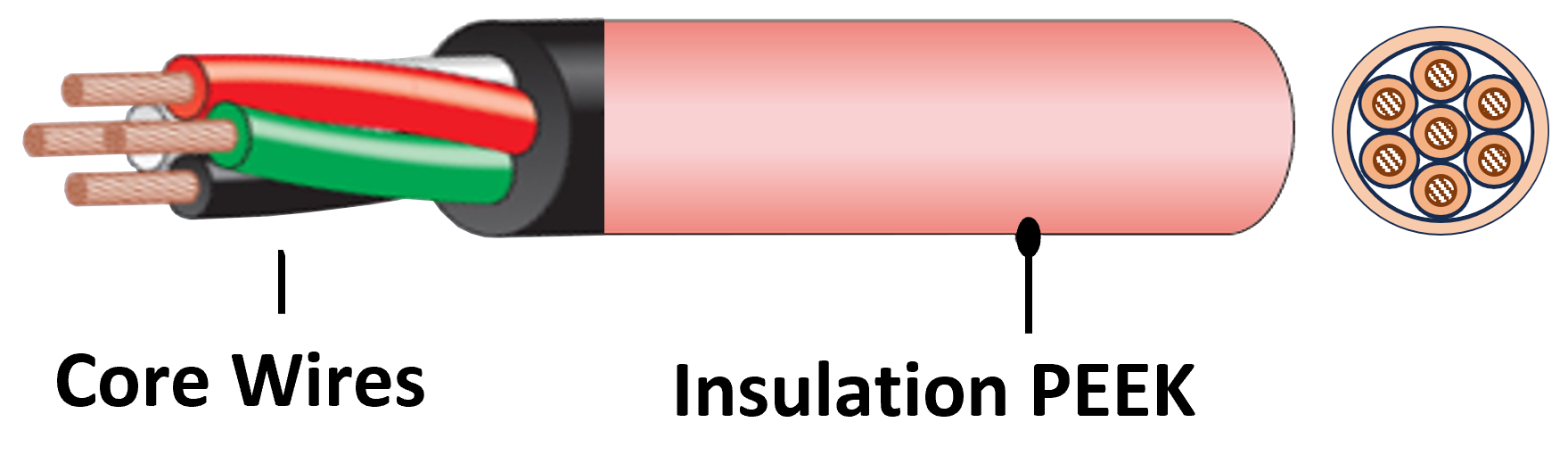

Structure

Specification

1. Temperature resistance level

Temperature range -70 ~ +260℃。

At an accelerated aging temperature of 150°C, a heat aging time standard of 1100 to 1300 hours can be achieved.

Withstand voltage level: 300V 600V.

2. Products and specifications meet standards

- Complying with the 4th generation nuclear power plants, it has a durability of more than 60 years at an operating temperature of 90°C.

-

Radiation resistant, with high activation energy between 2.0 and 2.8 eV.

-

Gamma radiation resistance: 850KGy can be used for a long time.

-

Complies with safety standards for nuclear power plants, LOCA (Loss of Coolant Accident) testing.

-

Comply with Design Basis Event (DBE) testing for nuclear power plants.

3. Test conditions

- Use the Arrhenius model to determine the accelerated aging (deterioration) temperature and time according to IEEE standards.

- According to Thermogravimetric Analysis (TGA) or elongation retention;

- Elongation Retention calculates the activation energy of the insulation coating material.

Application

Single-core wires or multi-core cables are used in nuclear power plants.

1. Advantages

- The activation energy of PEEK insulator is between 2.0 and 2.8 eV, which is better than traditional EPR, CR, and CSP insulating materials.

-

The elongation of PEEK insulation is between 150%~200%.

-

Due to its high activation energy, PEEK insulators provide long-term durability of more than 60 years at the normal operating temperature of 90°C in nuclear power plants.

-

When exposed to a total integrated dose of 300Mrad of gamma radiation, the insulation will not crack when bent, and it is radiation resistant and crack resistant. It can withstand 850KGy of gamma radiation and can be used for a long time.

-

Conforms to the 2.5 kV/5min underwater withstand voltage test.

-

The multi-core cable combustion test passed the Class A combustion test in the IEC60332.3 standard.

Technical parameters:

| Technical parameters |

Size

AWG |

Core

Dimeter |

Cross-

section |

Stranded

Concentric) |

Number of core

wires and nominal

cross-section |

Insulation |

Sheath |

| Thickness |

Outer

diameter D |

Thickness |

outer diameter D |

| min |

aver. |

max |

| --- |

mm |

mm2 |

--- |

mm2 |

mm |

mm |

mm |

| 14 |

2.05 |

2.50 |

19/0.41 |

2✖2.50 |

>0.35 |

2.75 |

>0.35 |

|

6.20 |

|

| |

|

19/0.41 |

3✖2.50 |

>0.35 |

2.75 |

>0.35 |

|

6.30 |

|

| |

|

19/0.41 |

4✖2.50 |

>0.35 |

2.75 |

>0.35 |

|

7.40 |

|

| ~ |

| 29 |

0.28 |

0.06 |

7/0.12 |

2✖0.06 |

|

|

>0.25 |

2.40 |

|

2.50 |

|

|

7/0.12 |

3✖0.06 |

|

|

>0.25 |

2.50 |

|

2.60 |

|

|

7/0.12 |

4✖0.06 |

|

|

>0.25 |

2.70 |

|

2.80 |

|

|

7/0.12 |

5✖0.06 |

|

|

>0.25 |

2.90 |

|

3.00 |

| |

*The number of cores, composition and insulation thickness can be specified by the customer.

*The insulation thickness of the general PEEK insulated wire without adhesive layer ranges from 0.025~2.032mm, and the AWG size is #3~#40.

|